Damatomacchine Forum iegādāties lietotu (688)

Kārtot rezultātus

- Zemākā cena Augstākā cena

- Jaunākie sludinājumi Senākie sludinājumi

- Īsākais attālums Maksimālais attālums

- Jaunākais ražošanas gads Vecākais ražošanas gads

- Jaunākais atjauninājums Vecākais atjauninājums

- Ražotāji no A līdz Z Ražotājs no Z līdz A

- Atbilstība

- Zemākā cena

- Cena

- Augstākā cena

- Cena

- Jaunākie sludinājumi

- Publicēšanas datums

- Senākie sludinājumi

- Publicēšanas datums

- Īsākais attālums

- Attālums

- Maksimālais attālums

- Attālums

- Jaunākais ražošanas gads

- Izgatavošanas gads

- Vecākais ražošanas gads

- Izgatavošanas gads

- Jaunākais atjauninājums

- Pēdējoreiz atjaunots

- Vecākais atjauninājums

- Pēdējoreiz atjaunots

- Ražotāji no A līdz Z

- Ražotājs

- Ražotājs no Z līdz A

- Ražotājs

- Apzīmējums no A līdz Z

- Apzīmējums

- Nosaukums no Z līdz A

- Apzīmējums

- Modelis no A līdz Z

- Modelis

- Modelis no Z līdz A

- Modelis

- Zemākā atsauce

- reference

- Augstākā atsauce

- reference

- Īsākais darbības laiks

- Darba laiks

- Garākā darbības ilgums

- Darba laiks

- Atbilstība

- Atbilstība

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata šūna

TiraTCZ 4012

Zvanīt

Stāvoklis: labi (lietots), TIRA

Type: Walk-in Climate Simulation Chamber TCZ 4012 S(m)

Technical Data:

Temperature range: -40...+120 °C

Temperature tolerance: +/- 1.0°C

Rate of temperature change: 1 K/min

Humidity range: 10...approx. 95 % rH

Humidity tolerance: +/- 5.0 % rH

Dimensions:

Test chamber volume: 13 m³

Isdpfxeuvipwj Afzetr

External dimensions (W x D x H): approx. 2260 mm x 3850 mm x 2780 mm

Test chamber (W x D x H): approx. 2254 mm x 2645 mm x 2251 mm

Door opening (W x H): approx. 2251 mm x 2254 mm

Condition: used

Scope of delivery: (See picture)

(Specifications subject to change and errors excepted!)

For further questions, feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Sāls smidzināšanas kamera / klimata maiņas iekārta

WeissSC/KWT 450

Zvanīt

Stāvoklis: ļoti labs (lietots), Weiss

Type: SC/KWT 450

Salt Spray Chamber

Technical Data:

Test chamber volume: 450 liters

Max. load: 100 kg

Brine reservoir: 180 liters

Itodpow Hz Trjfx Afzjr

External dimensions: Height 920 mm, Width 1930 mm, Depth 800 mm

Test chamber dimensions: Height 740 mm, Width 850 mm, Depth 570 mm

Fields of application:

Corrosion testing:

Salt spray test: ambient temperature up to +50°C

Condensation water test: ambient temperature up to +45°C

Humidifier: +75°C

Temperature constancy

The temporal temperature deviation is ± K.

Voltage: 1/N/PE AC 230V ±10% 50Hz

Rated power: 2.0 kW Rated current: 8.5 A

Combination:

Salt spray test SS: DIN 50021

Condensation water test KFW: DIN 50017

Standard climate (ventilation): DIN 50014

Weight: 180 kg

Condition: used

Scope of delivery: (see picture)

(Subject to changes and errors in the technical data and information!)

Please feel free to contact us by phone for further questions.

Mazā sludinājuma

Borken

Borken

1 273 km

Temperatūras skapis 990 litri

WeissWT3-1000/40 -40°C bis +180°C

Zvanīt

Stāvoklis: ļoti labs (lietots), Weiss

Model: WT3-1000/40

Weiss Temperature Test Chamber with S!MCON / 32-control, Water-cooled

Control Unit: "Touch Panel"

All control and operation commands can be executed on the "Touch Panel" control unit simply by touching the function icons.

Adjustable Feet

To compensate for floor unevenness and ensure sufficient ventilation of the machine section, the test chamber comes equipped with adjustable feet.

Feedthroughs

The chamber is fitted with feedthroughs on the right and left sides. These allow measuring cables and test equipment to be routed into the test chamber.

Standard feedthroughs installed:

R1: nominal width 125 mm

L1: nominal width 50 mm

Test Chamber Volume: approx. 990 liters

Test Chamber Dimensions: Height 950 mm, Width 1100 mm, Depth 950 mm

External Dimensions: Height 2000 mm, Width 1415 mm, Depth 2105 mm

Temperature Test Data:

Temperature Range: -40 to +180 °C

Temperature Deviation over Time at Workspace Center: ± 0.1 to ± 0.5 K

Spatial Temperature Deviation: ± 0.5 to ± 1.5 K

Temperature Change Rate:

Heating: 4.0 K/min

Cooling: 3.0 K/min

Maximum Heat Compensation: 4500 W

Operational Data:

Test Chamber Lighting: Halogen bulbs 2x 24V, 50W

Rated Voltage: 3/N / PE AC 400 V ± 10% 50 Hz

Rated Current: 22.0 A Rated Power: 11.5 kW

Fuse (on-site): 32 A slow-blow

Sound Pressure Level approx.:

Measured at 1m distance from the front, 1m height: 56 dB(A)

Refrigerant: R-404A

Weight: 840 kg

For your safety as a buyer, please note the following:

The following actions are performed on all chambers we offer prior to sale:

1. Functional check and replacement of necessary components

2. If required, new filling with legally compliant refrigerant

Iedpfjthhw Aex Afzotr

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see image)

(Specifications and technical data are subject to change and error!)

We are happy to answer further questions by phone.

Uzziniet tagad

+44 20 806 810 84

+44 20 806 810 84

Ievietot sludinājumu tagad

*par sludinājumu/mēnesī

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata skapis 138 litri

CLIMATSEXCAL 1413-HA -40 bis 180°C

Zvanīt

Stāvoklis: ļoti labs (lietots), Climats

Type: EXCAL 1413-HA

Climate Chamber, Air-cooled

The EXCAL is equipped with a 15-inch capacitive multitouch panel PC, SSD storage, Windows 7, and 2 USB ports. This makes it fully up-to-date with the latest technology.

Technical specifications:

Test chamber dimensions: Width 550 mm x Depth 500 mm x Height 500 mm

Housing dimensions: Width 820 mm x Depth 1375 mm x Height 1730 mm

Viewing window: 350 x 380 mm

Volume: 138 liters

Standard port built-in

R1: 80 mm ∅

L1: 80 mm ∅

Specifications for temperature tests:

Temperature range: -40°C to +180°C

Temporal temperature fluctuation: ± 0.1 to ± 0.3 K

Spatial temperature uniformity: ± 0.5 to ± 1.8 K

Temperature change rate:

Heating: 15 K/min

Cooling: 10 K/min

Specifications for climatic tests:

Temperature range: +10°C to +90°C

Humidity range: 10 to 98% r.h.

Operational data:

3/N/Ph+T 400V ±10% 50 Hz

Nominal power: 9.8 KVA

Itsdpfjv Dt T Tex Afzsr

Refrigerants: R-404A / R-23

Weight: 430 kg

Important safety information for buyers:

The following procedures are carried out on all chambers offered by us prior to sale:

1. Functional check and replacement of necessary components

2. If required, new filling with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see picture)

(Specifications and data subject to change and errors reserved!)

We are happy to answer any further questions by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Temperatūras testa kamera 335 litri

VötschVT 4034 -40°C..+180°C

Zvanīt

Stāvoklis: ļoti labs (lietots), Vötsch

Model: VT 4034

Vötsch Temperature Cabinet VT 4034, Air-cooled

Refrigerant: converted to R-452A

Internal dimensions: height 750 mm, depth 765 mm, width 580 mm

External dimensions: height 1780 mm, depth 1595 mm, width 865 mm

Temperature range: -40°C to +180°C

Temperature deviation:

Temporal: ± 0.1 to ± 0.5 K

Spatial: ± 0.5 to ± 2.0 K

Heating rate: 3.2 K/min

Cooling rate: 3.5 K/min

Maximum load (evenly distributed across the surface):

Test chamber floor: 60 kg

Per shelf: 30 kg

Total load on shelf supports: 80 kg

Test chamber lighting: Halogen bulb 24V, 50W

Rated voltage: 3/N/PE AC 400V ± 10% 50 Hz

Rated power: 4.1 kW

Rated current: 12.5 A

On-site fuse: 16 A slow-blow

Refrigerant: R-452A

Weight: 490 kg / 335 liters

Important safety information for buyers:

Itsdswd Hpaepfx Afzer

The following procedures are carried out on our offered chambers in advance:

1. Function check and replacement of necessary components

2. If required, refill with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see picture)

(Technical specifications and data subject to change and errors excepted!)

For further questions, please feel free to contact us by phone.

Atklājiet vēl vairāk lietotu iekārtu

Mazā sludinājuma

Borken

Borken

1 273 km

Unichiller cirkulācijas dzesētājs

HuberUnichiller 030TW

Zvanīt

Stāvoklis: ļoti labs (lietots), Huber

Type: 030TW

Huber Unichiller 030TW – Recirculating Chiller / Cooling Thermostat

For sale is a Huber Unichiller 030TW, a powerful and efficient recirculating chiller for laboratory and industrial applications. The device is designed for continuous operation and offers consistent cooling performance with high energy efficiency.

Features & Functions:

- Modern touchscreen control with favorites, timer, data logging, and remote control options

- Robust, closed cooling system for reliable continuous operation

- Environmentally friendly refrigerant

- Suitable for ambient temperatures up to +40°C

- Ideal for laboratories, chemistry, engineering, and process cooling

Technical Data:

- Temperature range: –20°C to +40°C

- Temperature stability: ±0.5 K

- Cooling capacity:

- 3 kW at +15°C

- 2.75 kW at 0°C

- 2 kW at –10°C

- 1 kW at –20°C

- Circulation pump: max. 30 l/min at 4.1 bar

- Controller: Pilot ONE touchscreen controller (5.7″ color display)

- Connections: Ethernet, USB, RS-232, Pt100

- Refrigerant: R449A (CFC- and HCFC-free, eco-friendly)

- Dimensions (W × D × H): 400 × 440 × 1230 mm

- Weight: approx. 137 kg

Isdpfx Aew S Efbofzjtr

- Condition: used

- Scope of delivery: (See picture)

- Huber Unichiller 030TW

- Power cable

(Subject to modifications and errors in the technical data; specifications are subject to change!)

We are happy to answer further questions for you by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Korozijas / kondensācijas pārbaudes ierīce

Gebr. LiebischK1000 M-TR / 4203.6101

Zvanīt

Stāvoklis: ļoti labs (lietots), Liebisch

Type: K1000 M-TR / 4203.6101

USED Liebisch K1000 M-TR Constacon – Manual Chest-Type Condensation Test Chamber

Corrosion/Condensation Test Device

(Chamber volume: 1000 l)

Itjdjw Tbdpepfx Afzsr

Item Description:

For sale is a used Liebisch K1000 M-TR, a sturdy and high-quality chest-type chamber

suitable for conducting condensation water tests.

Ideal for laboratories, quality control, or industrial applications.

Technical Data & Features

Model Variant:

Constacon K 1000 M-TR – Condensation Water Chambers without Ventilation

Chamber volume: approx. 1000 liters

Operation: Manual (Type M-TR)

External dimensions (W × D × H):

2600 × 1120 × 1210 mm

Internal test chamber dimensions (W × D × H):

1535–1425 × 800–780 × 660–650 mm

Test Standards:

For condensation (Constacon): DIN 50958, DIN EN ISO 6270-1/-2

Control:

Simple manual control panel – Parameters such as temperature and operating mode are set directly on the unit.

Temperature Control:

PID regulated, typical setpoints:

Condensation tests: approx. 40°C (up to max. 50°C)

Heat-up time: about 1 hour

Weight: approx. 400 kg

Condition: used

Scope of delivery: (See picture)

(Subject to prior sale and technical data may be subject to errors or changes!)

Further questions can be answered by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Koordinātu mērīšanas iekārta

ZeissO-INSPECT 442

Zvanīt

Stāvoklis: ļoti labs (lietots), ZEISS Coordinate Measuring Machine

Type: O-INSPECT 442

Machine Description: Coordinate Measuring Machine

Machine Type: O-INSPECT 442

The ZEISS O-INSPECT multi-sensor measuring machine enables optimal optical or tactile measurement of all features. The CALYPSO software allows for simultaneous display of actual condition, target profile, and deviations, making measurement results easy to identify and interpret.

General Data:

Dimensions: Width 1055 mm, Length 1351 mm, Height 1770 mm

Measuring Range: X 400 mm, Y 400 mm, Z 200 mm

Weight:

CMM 800 kg

Ijdow Titlopfx Afzetr

Workpiece max. 20 kg

CMM noise level < 70 dBA

Electrical Data:

Supply voltage: 100, 110, 120, 125, 230, 240 V~ (±10%)

Current type: 1 / N / PE

Frequency: 50 to 60 Hz (±3.5%)

Max. power consumption: 1500 VA

Fuses:

At 230 V or 240 V: 16 A

At 100 V or 125 V: 15 A

Traverse Speed:

Creep speed (SLOW function): 0 to 5 mm/s

Setup mode: 0 to 70 mm/s

Standard measurement mode:

Axis (X, Y) max. 200 mm/s

Axis (Z) max. 50 mm/s

Axis (3D) max. 287 mm/s

Environmental Conditions:

The following conditions must be met for flawless operation of the CMM:

Ambient temperature for standby: +17°C to +35°C

Relative humidity: 40% to 70% (non-condensing)

Room temperature for measurement: 20°C ±1 K

Altitude above sea level:

100–125 V: max. 3000 m

230–240 V: max. 2000 m

Probe system:

Probe system: CFS

Probe type data:

Probe type CFS 2mm

Measuring range 2 mm, working distance 61 mm, measuring spot diameter 12.5 µm

Measurable surface inclination relative to irradiation: 90 ±15°

Measuring range 3 mm, working distance 22.5 mm, measuring spot diameter 12 µm

Measurable surface inclination relative to irradiation: 90 ±30°

Measuring range 10 mm, working distance 70 mm, measuring spot diameter 24 µm

Measurable surface inclination relative to irradiation: 90 ±20°

Values for surface inclination are limit values depending on the reflective properties of the workpiece surface.

Rotary Table:

Weight and resolution

Rotary table weight: 7 kg

Resolution: 0.15’’

Dynamics:

Angular speed max. 50°/s

Rotational speed: 8.3 min⁻¹

Scope of Delivery:

In the standard configuration, the O-INSPECT coordinate measuring machine is supplied with the following components:

Coordinate measuring machine (CMM)

Controller (integrated)

Control panel

Computer with peripherals

Software – CALYPSO 5.2

Documentation

Probe system

Reference stylus

Calibration standard

Calibration template

Scope of delivery: (ZEISS coordinate measuring machine as pictured)

Condition: used

(Technical data and specifications subject to change and errors!)

Please inquire about transport options before purchase.

We are happy to answer further questions for you by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata kamera

VötschVC³ 4060

Zvanīt

Stāvoklis: ļoti labs (lietots), Heraeus Vötsch Climate Test Chamber

We offer here a Heraeus Vötsch climate test chamber.

Heraeus Vötsch climate test chamber with humidity control (water-cooled)

Test chamber internal dimensions: Width 800 mm x Depth 800 mm x Height 950 mm

Housing dimensions: Width 1,090 mm x Depth 1,960 mm x Height 1,995 mm

Specifications for temperature tests:

Temperature range: -45°C to +180°C

Itodpfxjmt Du To Afzjr

Temporal fluctuation: ±0.1 to ±0.5 K

Spatial fluctuation: ±0.5 to ±1.5 K

Temperature change rate according to IEC 60068-3-5:

Heating: 4.0 K/min

Cooling: 3.0 K/min

Specifications for climate tests:

Temperature range: -45°C to +180°C

Temperature deviation at steady state, according to IEC 60068-3-5 (depending on test chamber temperature)

Temperature range: -10°C to +95°C

Temporal fluctuation: ±0.1 to ±0.3 K

Spatial fluctuation: ±0.5 to ±1.0 K

Humidity range: 10% to 98% r.H.

Humidity deviation over time: +1 to ±3

Electrical connection:

Rated voltage: 3/N/PE AC 400V ±10% 50Hz

Rated power: 7.8 kW

Rated current: 15.0 A

Refrigerant: R452A

Test chamber volume: approx. 600 liters

Net weight: approx. 620 kg

Type: VC³ 4060

For your safety as a buyer, please note the following information!

The following procedures are carried out in advance on all of our offered chambers:

1. Functional check and replacement of necessary components

2. New filling with legally compliant refrigerant

3. Leak test with certificate

4. After a successful check, the chambers undergo a test run, which is monitored using calibrated instruments.

Condition: used

Scope of delivery: as shown (see picture)

(Modifications and errors in technical data and specifications excepted!)

If you have any further questions, we will be happy to answer them by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Siltuma skapis ar slāpekļa piegādi

VötschTU 60/60 G-ISO Temp. 250°C

Zvanīt

Stāvoklis: ļoti labs (lietots), Here we offer a Vötsch heating cabinet with nitrogen supply.

Vötsch heating cabinet with nitrogen supply

Rated temperature: 250°C

Itodpfxod Ngg To Afzer

Rated current: 10 A

Connected load: 6.3 kVA

Rated voltage: 400V 3(N)PE AC 50/60Hz

Rated power: 6 kW

Type: TU 60/60 G-ISO

Condition: used

Scope of delivery: (see picture)

(Subject to changes and errors in the technical data and specifications!)

For further questions, please feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Klimatiskā testa kamera 335 litri ar mitrumu

VötschVCS 7034-5 -70°C bis +180°C

Zvanīt

Stāvoklis: labi (lietots), Vötsch

Type: VCS 7034-5

Climate Test Chamber, Water-Cooled

Vötsch VCS 7034-5

Test Chamber Volume: 335 liters

Performance for Temperature Testing:

Temperature range: -70 to +180°C

Temporal temperature deviation: K ±0.1 to ±0.5

Spatial temperature deviation: K ±0.5 to ±2.0

Temperature gradient: 1 to 4

Rate of change:

Cooling: 6.7 K/min

Heating: 6.8 K/min

Heat compensation at +20°C: 3000 W / at -20°C: 3000 W

Temperature calibration values: +23°C and +80°C

Performance for Climate Testing:

Temperature range: +10 to +95°C

Temporal temperature deviation: ±0.1 to ±0.3 K

Spatial temperature deviation: ±0.5 to ±1.0 K

Temperature gradient: 1 to 2 K

Humidity range: 10 to 98%

Temporal humidity deviation: ±1 to ±3%

Dew point range: -3 to +94°C

Heat compensation: 400 W

Climate calibration values: +23°C / 50% r.h. and +95°C / 50% r.h.

Test chamber dimensions: Width: 580 mm, Depth: 765 mm, Height: 750 mm

External dimensions: Width: 870 mm, Depth: 1595 mm, Height: 1775 mm

Electrical connection: 3/N/PE AC, 400 V ±10% 50 Hz

Rated power: 10 kW

Rated current: 21 A

Sound pressure level: 64 dB(A)

Itodpouudx Dofx Afzer

Cooling water consumption: 1.4 m³/h

Refrigerant: R-404A / R-23

Condition: used

Scope of delivery: (See image)

(Subject to technical changes and errors in specifications!)

If you have any further questions, we will be happy to answer them by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata pārbaudes kamera

VötschVCS 7034-5

Zvanīt

Stāvoklis: lietots, Vötsch

Model: VCS 7034-5

Climate Test Chamber, water-cooled

Test chamber volume: 335 liters

Specifications for temperature tests:

Temperature range: -70 to +180°C

Temporal temperature deviation: K ±0.1 to ±0.5

Spatial temperature deviation: K ±0.5 to ±2.0

Temperature gradient: 1 to 4

Change rate:

Cooling: 6.7 K/min

Heating: 6.8 K/min

Heat compensation at +20°C: 3000 W / at -20°C: 3000 W

Temperature calibration values: +23°C and +80°C

Specifications for climate tests:

Temperature range: +10 to +95°C

Temporal temperature deviation: ±0.1 to ±0.3 K

Spatial temperature deviation: ±0.5 to ±1.0 K

Temperature gradient: 1 to 2 K

Humidity range: 10 to 98%

Temporal humidity deviation: ±1 to ±3%

Dew point range: -3 to +94°C

Heat compensation: 400 W

Climate calibration values: +23°C / 50 % RH and +95°C / 50 % RH

Test chamber dimensions: Width 580 mm, Depth 765 mm, Height 750 mm

External dimensions: Width 870 mm, Depth 1595 mm, Height 1775 mm

Electrical connection: 3/N/PE AC, 400 V ±10% 50 Hz

Rated power: 10 kW

Rated current: 21 A

Sound pressure level: 64 dB(A)

Cooling water consumption: 1.4 m³/h

Refrigerant: R404A / R-23

Important information for your peace of mind as a buyer:

Itjdpexqzbbofx Afzor

The following procedures are performed on all our offered chambers prior to sale:

1. Functional check and replacement of necessary components

2. Recharging with legally compliant refrigerant if required

3. Leak test with certificate

4. Upon successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see image)

(Specifications and technical data subject to change or error!)

For further questions, please feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Temperatūras testa kamera 335 litri

Vötsch-70°C bis +180°C VTS 7034-5

Zvanīt

Stāvoklis: ļoti labs (lietots), Type: VCS 7034-5

Climate test chamber, water-cooled

Test chamber volume: 335 liters

Performance for temperature tests:

- Temperature range: -70 to +180°C

- Temperature deviation over time: K ±0.1 to ±0.5

- Temperature deviation spatial: K ±0.5 to ±2.0

- Temperature gradient: 1 to 4

- Change rate:

- Cooling: 3.5 K/min

- Heating: 6.8 K/min

- Heat compensation at +20°C: 3000 W / at -20°C: 3000 W

- Temperature calibration values: +23°C and +80°C

Performance for climate tests:

- Temperature range: +10 to +95°C

- Temperature deviation over time: ±0.1 to ±0.3 K

- Temperature deviation spatial: ±0.5 to ±1.0 K

- Temperature gradient: 1 to 2 K

- Humidity range: 10 to 98%

- Humidity deviation over time: ±1 to ±3%

- Dew point range: -3 to +94°C

- Heat compensation: 400 W

- Climate calibration values: +23°C / 50% RH and +95°C / 50% RH

Test chamber dimensions:

- Width: 580 mm

- Depth: 765 mm

- Height: 750 mm

External dimensions:

- Width: 870 mm

- Depth: 1595 mm

- Height: 1775 mm

Feedthroughs:

- 1 feedthrough ∅ approx. 50 mm, left

- 2 feedthroughs ∅ approx. 125 mm, left

- 1 feedthrough ∅ approx. 125 mm, right

Electrical connection: 3/N/PE AC, 400 V ±10% 50 Hz

Rated power: 10 kW

Rated current: 21 A

Sound pressure level: 64 dB(A)

Cooling water consumption: 1.4 m³/h

Refrigerants: R404A / R-23

For your safety as a buyer, the following information:

Isdjxufypopfx Afzjtr

The following points are carried out on our offered chambers in advance:

1. Functional check and replacement of necessary components

2. If required, refilling with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (see picture)

(Subject to changes and errors in the technical data and specifications!)

For further questions, please feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

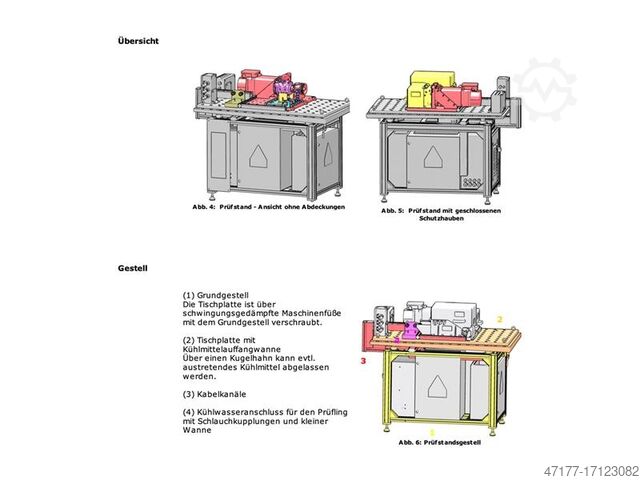

48V siksnas startera ģeneratora testa stends

KübrichKomponentenprüfstand

Zvanīt

Stāvoklis: ļoti labs (lietots), Kübrich Test System 48V Belt Starter Generator – Component Test Bench

Test Bench Details: (See image 13)

Frame with

(1) Mounting device for a belt starter generator

(2) Load machine

(3) Belt

(4) MP1: Control cabinet

(5) MP3: Control cabinet for system control, interface panel with main switch, I/O

(6) MP2: Control cabinet with Simotion

(7) MP4: Control cabinet with DC-DC converter

Isdpfjumv Emjx Afzjtr

(8) H3: Measurement technology box

(9) H4: Interface box

Intended Use:

The test bench is used for conducting tests on belt starter generators during development.

Technical Data:

Electrical connection data

Supply: 400 V / 32 A

Battery simulation: 0 - 60 V

Current: 0 - 250 A (continuous)

Current: 330 A (short-term, less than 1 s)

Control voltage 24 V

Mechanical performance data according to load machine data sheet

Note a gear ratio of 1:2 to the DUT (Device Under Test) shaft.

Speeds:

Load machine:

Manual mode: 0 - 50 rpm

Automatic mode: 0 - 10,000 rpm

DUT motor:

Manual mode: 0 - 100 rpm

Automatic mode: 0 - 20,000 rpm

Dimensions and weight:

Width: 850 mm Height: 1386 mm Length: 1687 mm

Weight: approx. 1.2 t

Condition: used

Scope of delivery: (see image)

(Specifications and technical details subject to change and errors excepted!)

If you have further questions, we will be happy to answer them by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Šeikeri

LDSV721 / TK 8000/-50/120

Zvanīt

Stāvoklis: labi (lietots), LDS + Andreas Schmid

Tips: LDS Shaker V721 + TK 8000/-50/120 (temperature range: -55°C to +140°C)

Shaker unit:

- Vibration exciter: 4x LDS V721, air-cooled

- Amplifier: PA 1000L

- Controller: IMV K2 MIMO (Multi Input Multi Output)

- Software: IMV K2

- Excitation modes: Sine / Random / Shock / Real-time profiles

- Force vector per shaker: 2.9 kN (Peak Sine) / 1.9 kN (RMS Random) / 4.6 kN (Peak Shock)

- Maximum payload: 100 kg per shaker

- Acceleration: up to 44 g RMS / 66 g Peak

- Velocity: max. 0.7 m/s

- Displacement amplitude: max. 25.4 mm p-p (1 inch)

- Frequency range: 5...4000 Hz

- Mounting platform for specimens: 1000 x 1000 mm aluminum profile frame

- Special features:

- The four shakers can be operated synchronously or asynchronously with the MIMO controller.

- With an aluminum profile frame, a mounting area of 1 x 1 m² can be realized for large test specimens.

- Without the profile frame, mobile use as a modal shaker for large specimens (e.g., complete vehicles) is possible.

- Lightweight shaker elements allow excitation frequencies up to 4000 Hz.

- Weight: 2000 kg

Climatic chamber:

- Manufacturer: Andreas Schmid Anlagentechnik GmbH

- Type: TK 8.000/-50/120 / Monoblock, welded

Dimensions (mm): Width Depth Height

- Test chamber: 2000 2000 2000 (8m³)

Itedpjur Hrbjfx Afzsr

- External dimensions without base frame: 2340 3600 2800

- External dimensions with base frame: 2340 3600 3800

- Dimensions of equipment unit: 1200 2400 2200

- Door: 2000 2000

- 2x inspection windows in the door: 460 460

- Weight: 4,500 kg

- Insulation: 140 mm PU, CFC-free, B1 as per DIN 4102

- Outer cladding: 0.6 mm sheet steel, painted to RAL 7035

- Temperature range: -55°C to +140°C

- Temperature stability: ±0.5 K over time

- Climate range: +10°C to +95°C

- Humidity range: 10% to 95% RH

- Refrigerant: R404A, 29 kg

- Total weight: 6,500 kg

Condition: used

Scope of supply: (see picture)

Sample images! Current pictures to follow!

(Specifications and technical data subject to change and errors!)

For further inquiries, we will be happy to assist you by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Temperatūras testa kamera

VötschVTS 7034-5

Zvanīt

Stāvoklis: labi (lietots), Heraeus Vötsch

Model: VTS 7034-5

Heraeus Vötsch Temperature Test Chamber, Water-Cooled

Temperature range: -70°C to +180°C

Temporal temperature deviation: ±0.1 to ±0.5 K

Spatial temperature deviation: ±0.5 to ±2.0 K

Cooling rate: 5.0 K/min

Isdpfsun Izcox Afzjtr

Heating rate: 6.5 K/min

Heat compensation at +20°C: 3000 W

Heat compensation at -20°C: 3000 W

Test chamber dimensions: Width 580 mm x Depth 765 mm x Height 750 mm

External dimensions: Width 870 mm x Depth 1595 mm x Height 1775 mm

Test chamber volume: 335 litres

Rated voltage: 3/N/PE AC, 400V ±10%, 50Hz

Rated power: 10 kW

Rated current: 21 A

Sound level at 1m distance (free field measurement): < 69dB (A)

Side port: 5.5 cm / 12.5 cm

Chamber is water-cooled

Refrigerants: R-404A and R 23

Weight: approx. 570 kg

Important information for your security as a buyer:

The following checks are routinely performed on all our listed chambers:

1. Functional check and replacement of necessary components

2. Refill with legally compliant refrigerant

3. After successful inspection, the chambers undergo a trial run monitored with calibrated equipment.

Condition: used

Scope of delivery: (see picture)

(Specifications and data are subject to change and errors are reserved!)

For further questions, feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Laboratorijas barošanas avots

EA Elektro-AutomatikEA-EL 9080-170 B

Zvanīt

Stāvoklis: labi (lietots), EA Elektro Automatik

Model: EA-EL 9080-170 B

Electronic DC Load, USB / Analog / Master-Slave, Programmable, 80V, 170A, 2.4kW

Technical Data:

Mains voltage: 90...264 V AC

Mains connection type: socket

Mains frequency: 45...65 Hz

Mains fuse: T 6.3

Power consumption: Max. 90 W

Leakage current: < 3.5 mA

DC Input

Input voltage: 80 V

Input power: 2400 W

Input current: 170 A

Overvoltage protection range: 0...1.03 * UNominal

Overcurrent protection range: 0...1.1 * INominal

Overpower protection range: 0...1.1 * PMax

Max. permissible input voltage: 88 V

Min. input voltage for IMax: Approx. 2.2 V

Temperature coefficient of set values Δ / K Current / Voltage: 30 ppm

Iodpeuv Eudefx Afzotr

Voltage Control

Adjustment range: 0...81.6 V

Stability at ΔI < 0.05%

Accuracy (at 23 ± 5°C): ≤ 0.1% UNominal

Display: Accuracy ≤ 0.1% UNominal

Remote sense compensation: Max. 5% UNominal

Current Control

Adjustment range: 0...173.4 A

Stability at ΔU < 0.1% INominal

Accuracy (at 23 ± 5°C): ≤ 0.2% INominal

Display: Accuracy ≤ 0.1% INominal

Rise time 10...90% INominal < 23 μs

Fall time 90...10% INominal < 46 μs

Power Control

Adjustment range: 0…2428 W

Accuracy (at 23 ± 5°C): < 0.5% PMax

Display: Accuracy ≤ 0.2% PMax

Resistance Control

Adjustment range: 0.04…15.3 Ω

Accuracy (at 23 ± 5°C): ≤1% of resistance end value + 0.3% of INominal

Display: Accuracy included in setting value

EL 9080-170 B:

Analog interface:

Setpoint inputs U, I, P, R

Actual value outputs U, I

Control signals: DC on/off, remote operation on/off, R-mode on/off

Status signals: CV, OVP, OCP, OPP, OT, PF, DC on/off

Galvanic isolation to device: Max. 400 V DC

Sampling rate setpoint inputs: 500 Hz

Isolation:

DC input to housing: DC minus: permanent max. ±400 V; DC plus: permanent max. ±400 V + max. input voltage

AC input to DC input: Max. 2500 V, short term

Environment:

Cooling type: Temperature-controlled fans

Operating temperature: 0...50 °C

Storage temperature: -20...70 °C

Digital Interfaces

Built-in: 1x USB-B for communication, 1x USB-A for functions, 1x Master-Slave-Bus

Slot for digital modules: Optional: CAN, CANopen, Profibus, Profinet, RS232, Ethernet, ModBus TCP, EtherCAT

Galvanic isolation to device: Max. 400 V DC

Connections:

Rear: Share-Bus, DC input, AC input, sense, analog interface, USB-B, master-slave bus, interface module slot

Front: USB-A

Dimensions:

Housing (WxHxD): 19" x 2 U x 464 mm

Total (WxHxD): 483 mm x 88 mm x 538 mm

Standards: EN 61010-1:2007-11, EN 61000-6-2:2005, EN 61000-6-3:2006 Class B

Weight: approx. 11 kg

Condition: used

Scope of delivery: (see picture)

(Subject to change and errors in the technical data!)

Further questions can be answered by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata skapis 335 litri

WeissWK-340/70 -70 °C bis +180 °C

Zvanīt

Stāvoklis: ļoti labs (lietots), Weiss

Type: WK-340/70

air-cooled

Test chamber volume approx. 335 litres

Test chamber dimensions: Height 750 mm, Width 580 mm, Depth 765 mm

External dimensions: Height 1,805 mm, Width 780 mm, Depth 1,700 mm

Specification values for temperature tests:

Temperature range: -70 to +180 °C

Temporal temperature fluctuation: ± 0.1 to ± 0.5 K

Spatial temperature fluctuation: ± 0.5 to ± 2.0 K

Temperature change rate (heating): 3 K/min

Temperature change rate (cooling): 2 K/min

Specification values for climate tests:

Temperature range: +10 to +95 °C

Humidity range: 10 to 98% rH

Temporal temperature fluctuation: ± 0.1 to ± 0.3 K

Spatial: ±0.5 to ±1 K

Humidity fluctuation at chamber centre: ± 1 to ± 3% rH

Electrical connection: 3/N/PE AC, 400 V ±10%, 50 Hz

Connected load: approx. 4.1 kW

Rated current: 14.0 A

Sound pressure level: approx. 60 dB(A)

Weight: approx. 500 kg

Refrigerants: R404A / R23

For your safety as a buyer, please note the following information!

The following procedures are carried out in advance on our offered chambers:

1. Functional check and replacement of necessary components

2. New filling with legally compliant refrigerant

3. After successful inspection, the chambers are subjected to a test run, which is monitored with calibrated instruments.

Condition: used

Scope of delivery: (See photo)

(Technical data subject to change and errors excepted!)

Isdov Uap Njpfx Afzetr

If you have any further questions, we will be happy to answer them by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Ar mitrumu 270 litri

VötschKlimaprüfschrank VCS³ 7027-10

Zvanīt

Stāvoklis: ļoti labs (lietots), Vötsch

Model: VCS³ 7027-10

Vötsch Climate Test Chamber, Water-cooled

With temperature change rate of 10 K/min

Temperature Test Data:

Temperature range: -72°C to +180°C

Temporal temperature deviation at the chamber center: ±0.3 K to ±0.5 K

Spatial temperature deviation: ±0.5 K to ±2.0 K

Temperature change rate:

Heating: 10 K/min

Cooling: 14.5 K/min

Climate Test Data:

Itsdev R Ty Tepfx Afzsr

Temperature range: +10°C to +95°C

(Extended climate range: 2°C/95% r.h. controlled for max 2 hours)

Temporal temperature deviation at the chamber center: ±0.2 K to ±0.3 K

Spatial temperature deviation: ±0.5 K to ±1.0 K

Temporal humidity deviation at the chamber center: ±1% to ±3% r.h.

Humidity range: 10% to 98% r.h.

(Extended climate range: 2°C/95% r.h. controlled for max 2 hours)

External dimensions: Width 780 x Depth 1895 x Height 1775 (mm)

Test chamber dimensions: Width 580 x Depth 615 x Height 750 (mm)

Test chamber volume: approx. 270 liters

Side port: 50 mm

Side port: 125 mm

Operating Data:

LED strip 24 V, 6.8 W / 2 x halogen bulb 24 V, 50 W

Rated voltage: 3/N/PE AC 400 V ±10 %, 50 Hz

Rated power: 14 kW

Rated current: 26 A

Required fuse (on-site): 63 A slow-blow

Refrigerants: R404A / R-23

Weight: approx. 835 kg

For your safety as the buyer, please note the following information!

The following procedures are performed on our offered chambers in advance:

1. Functional check and replacement of necessary components

2. If required, refilling with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers undergo a documented test run.

Condition: used

Scope of delivery: (See photo)

(Specifications and other details are subject to change and errors reserved!)

We are happy to answer further questions by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Rotācijas lāpstiņas vakuumsūknis

LeyboldTrivac D 40 B

Zvanīt

Stāvoklis: ļoti labs (lietots), Leybold Type: Trivac D 40 B

The TRIVAC B series are oil-sealed rotary vane vacuum pumps. The oil injected into the compression chamber serves for sealing, lubrication, and cooling purposes. The pump body is assembled from individual components without sealing elements. These parts are pinned to ensure easy disassembly and reassembly.

Ultimate pressure: 2 x 10⁻³ mbar

Motor: 3-phase, 230/400 V, 50/60 Hz

Pumping speed (50 Hz): 40 m³/h

Pumping speed (60 Hz): 48 m³/h

Environmentally Friendly:

- Quiet operation

- Vibration-free running

- Energy-efficient

Energy Efficiency:

- Low power consumption

- Minimal heat emission

Itedpfjvx Tduex Afzor

State-of-the-Art Vacuum Technology:

- High pumping speed up to ultimate pressure

- Low ultimate pressure, even with gas ballast

- High water vapor tolerance

- Continuous operation possible at up to 1000 mbar

- Integrated oil pump, forced-lubricated slide bearings

- Minimal air intake

- High leak tightness (4He-capable)

Technical Data:

Product: TRIVAC D 40 B

Inlet flange: DN 40 ISO-KF

Outlet flange: DN 40 ISO-KF

Nominal pumping speed at 50 Hz: 46.0 m³/h

Nominal pumping speed at 60 Hz: 55.0 m³/h

Pumping speed at 50 Hz: 40.0 m³/h

Pumping speed at 60 Hz: 48.0 m³/h

Ultimate partial pressure without gas ballast: 1.0 x 10⁻⁴ mbar

Ultimate total pressure without gas ballast: < 2.0 x 10⁻³ mbar

Ultimate total pressure with gas ballast: < 5.0 x 10⁻³ mbar

Water vapor tolerance at 50 Hz: 40.0 mbar

Water vapor tolerance at 60 Hz: 40.0 mbar

Water vapor capacity at 50 Hz: 1,184 g/h

Water vapor capacity at 60 Hz: 1,184 g/h

Oil capacity: min. 1.7 l / max. 2.6 l

Sound level as per DIN 45 635:

- without gas ballast: 57 dB(A)

- with gas ballast: 59 dB(A)

Power supply:

- 3-phase, 200 / 200-240 / 380-400 V ±10%, 50 Hz

- 3-phase, 200-240 / 380-480 V ±10%, 60 Hz

Motor power: 2.2 kW

Motor speed at 50 Hz: 1,430 rpm

Motor speed at 60 Hz: 1,735 rpm

Motor protection class: IP 55

Permissible ambient temperature: +12 to +40°C

Weight: 73.0 kg

Condition: used

Scope of delivery: (see pictures)

(Technical specifications subject to change and errors. All information provided without guarantee!)

For further questions, please feel free to contact us by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Temperatūras skapis 110 litri

VötschVT 7011 -70°C bis +180°C

Zvanīt

Stāvoklis: ļoti labs (lietots), Here we offer a Heraeus Vötsch temperature chamber.

Heraeus Vötsch Temperature Chamber, water-cooled

Test chamber volume: 110 liters

Internal dimensions: Width 560 mm, Depth 350 mm, Height 630 mm

External dimensions: Width 850 mm, Depth 1030 mm, Height 1640 mm

Temperature range: -70°C to +180°C

Temporal temperature deviation: ±0.1 to ±0.5 K

Spatial temperature deviation: ±0.5 to ±1.5 K

Temperature gradient: 1 to 3 K

Temperature change rate, cooling: 3.2 K/min

Temperature change rate, heating: 3.5 K/min

Refrigerants: R-404 A / R 23

Voltage: 1/N/PE AC 230V±10% 50Hz

Rated power: 1.8 kW

Rated current: 12 A

Model: VT 7011

Important information for you as the buyer:

The following points are carried out in advance on our offered chambers:

1. Function check and replacement of necessary components

Iodpshrdy Sefx Afzstr

2. New filling with legally compliant refrigerant

3. After successful inspection, the chambers undergo a test run monitored with calibrated devices.

Condition: used

Scope of delivery: (see picture)

(Subject to modifications and errors in technical data and specifications!)

Please feel free to contact us by phone for further questions.

Uzticamības zīme

Machineseeker sertificēti tirgotāji

Mazā sludinājuma

Borken

Borken

1 273 km

Putekļu pārbaudes kameras putekļu kamera

Testzentrum Baden Primus EngineeringDST350

Zvanīt

Stāvoklis: ļoti labs (lietots), Primus Engineering

Model: DST 350

This testing device is designed for performing IP protection class tests "Dust" according to, for example, DIN 40050 Part 9 and DIN EN 60529.

The test facility is intended for the testing of technical components under the influence of dust and vacuum within the limits specified in the technical data.

Operation / HMI

- Operator panel with screen and buttons

- Manual controllers

Itjdpfxsrt U Nuo Afzsr

- Stored test procedures

- Integrated vacuum circuit with flow measurement

Technical Data:

- Total electrical power: Max. 5 KW

- Connection voltage: 400V/50Hz 3-PH/PE (16A EEC outlet)

- Dimensions: Width approx. 920 mm, Depth approx. 710 mm, Height approx. 1,770 mm

- Test chamber dimensions: Width approx. 700 mm, Depth approx. 650 mm, Height approx. 770 mm

- Volume: approx. 350 l

- Weight: approx. 200 kg

- Vacuum: 0 to -100 mbar

- Suction air flow: 0 to approx. 5 l/min

- Operating climate range: Temperature: +12°C to +30°C; Humidity: 25% rel. H. to 75% rel. H., non-condensing

Protection class tests according to DIN 40050 Part 9 and DIN EN 60529 (VDE 0470 Part 1)

Dust test:

- Dust-protected IP5X and IP5KX

- Dust-tight IP6X and IP6KX

- With and without vacuum

Condition: used

Scope of delivery: (See image)

(Specifications and technical data subject to change and error!)

Should you have any further questions, we are happy to assist you by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

3D printeris

StratasysDimensio elite

Zvanīt

Stāvoklis: ļoti labs (lietots), Stratasys 3D printer Dimension Elite

We are offering you a Stratasys 3D printer Dimension Elite.

Stratasys 3D Printer Dimension Elite

The Dimension Elite 3D printer is part of the Design Series from Stratasys.

The Dimension Elite printer is ideal for printing 3D prototypes and modeling functional components,

such as medical devices, mobile electronic devices, or precision instruments.

Iedsk E H Iuopfx Afzjtr

With a simple click on "Print", the CAD file is prepared and the print process starts.

After easy removal of the soluble support material, a precise and detailed component emerges.

Manufacturer: Stratasys

Type: Professional operation

Material(s): ABS

Technology: Fused Deposition Modeling (FDM)

Assembly: Plug & Play

Dimensions: 686x914x1041 mm

Weight (kg): 136

Nozzle diameter (mm): -

Layer thickness (μm): 178

Speed (mm/s): -

Precision (μm): -

Filament diameter (mm): -

Maximum build volume (mm): 203x203x305

File format: .stl

Software: CatalystEX software

Connections: Ethernet

Operating system: Windows XP, Windows 7

Power requirements: 100 to 120 VAC, 60 Hz, at least 15 A on a dedicated circuit or 220 to 240 VAC, 50/60 Hz, at least 7 A on a dedicated circuit

Type: Dimension Elite

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data and information are reserved!)

We will be happy to answer further questions for you by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Termoplastiskais aplikators

BystronicTPA H

Zvanīt

Stāvoklis: ļoti labs (lietots), Bystronic

Model: ERMM180

Thermoplastic Applicator

Application Area

The thermoplastic applicator applies a thermoplastic material onto right-angled glass panes as part of a solar module production line. The material forms a seal with a second glass pane, which is applied in a subsequent production step. Feeding, application, and discharge of the panes occur on horizontally running belts/conveyors.

The thermoplastic applicator is a highly advanced machine that must meet numerous requirements with exceptional precision. Therefore, you should only process raw materials (glass, sealant) that meet the specifications listed on the following pages. This helps ensure high-quality and safe production.

Performance Data & Connection Values

- Maximum conveyor speed: 18 m/min

- Height of glass conveyor surface: 1100 mm

- Applied sealant bead height: 0.5 to 1.2 mm

- Maximum applied sealant bead width: 12.0 mm

- Required constant pneumatic inlet pressure: 6.5 to 8.0 bar

- Operating pneumatic pressure: 6.0 bar

Itsdpjd N Erpofx Afzer

- Compressed air consumption (normal operation): 10 NL/min

- Compressed air consumption (drum change): 500 NL/min

- Average energy consumption per hour: 10 kWh

- Working temperature for sealant: 110°C to 130°C

Ambient Conditions & Emissions

- Minimum ambient temperature: +15°C

- Maximum ambient temperature: +35°C

- Maximum relative humidity: 75 %

- Noise level: less than 70 dB(A)

Sealant Drum Requirements

- Design: Material drum with lid D18 according to DIN 6644 – with foot (F1) and smooth outer surface (smooth drum design)

- Capacity: 216 liters

- Internal diameter: 571.5 mm

- Height: 874 mm

- Minimum wall thickness: 1.25 mm

Processable Glass Panes

- Glass Type: Glass panes with a flat surface (float glass)

- Min./max. dimensions/geometries:

- Length: 1198 mm / 1200 mm

- Width: 498 mm / 600 mm

- Thickness: 1.8* mm / 5.0* mm

- Only thermoplastic sealants based on polyisobutylene (butyl) can be used. The material must be flowable within approx. 110°C–130°C and have a defined viscosity range.

- Only use materials which have proven effective in practice and are approved by both the material manufacturer and Bystronic for your intended application.

For detailed product descriptions as well as information on handling, storage, and disposal of the thermoplastic, please refer to the product information and safety data sheets provided by the manufacturers.

Portal Robot with Glass Conveyor – Dimensions

- Height x width x depth: 2800 x 1890 x 2735 mm

- Weight of portal robot: 850 kg

- Weight of glass conveyor: 1400 kg

Drum Pump Dimensions

- Height x width x depth: 3320 x 1060 x 1200 mm

- Weight (without drum): 850 kg

- Weight (with drum): 1100 kg

- Height H (drum pump FP1): 4400 mm

- Height H (drum pump FP2): 4000 mm

Control Cabinet Dimensions

- Height x width x depth: 2200 x 1800 x 600 mm

- Weight: 450 kg

The applicator was used with butyl material.

Condition: Used

From test laboratory, as new, only a few operating hours for testing!

Scope of delivery: (see image)

(Specifications and technical details subject to change and correction!)

Further questions can be answered by phone.

Mazā sludinājuma

Borken

Borken

1 273 km

Klimata pārbaudes kamera Temp. -70°C līdz +180°C

Vötsch 190 LiterVCS 7018-5

Zvanīt

Stāvoklis: ļoti labs (lietots), Heraeus Vötsch

Type: VCS 7018-5

Climate Test Chamber with Humidity, Water-Cooled

Test Chamber Dimensions: Width 580 mm x Depth 450 mm x Height 750 mm

Housing Dimensions: Width 870 mm x Depth 1280 mm x Height 1775 mm

Specifications for Temperature Testing:

Temperature Range: -70°C to +180°C

time deviation: ± 0.1 to ± 0.5 K

spatial deviation: ± 0.5 to ± 2.0 K

Temperature Gradient: 1 to 4 K

Temperature Change Rate according to IEC 60068-3-5

Heating: 7.5 K/min.

Cooling: 7.5 K/min.

Specifications for Climate Testing:

Temperature Range: +10 to +95°C

Humidity Range: 10 to 98% r.h.

Temporal Temperature Deviation: ± 0.1 to ± 0.3 K

Spatial Temperature Deviation: ± 0.5 to ± 1 K

Temperature Gradient: 1 to 2 K

Temporal Humidity Fluctuation: ± 1 to ± 3% r.h.

Dew Point Range: -3 to +94°C

Electrical Connection:

Rated Voltage: 3/N/PE AC 400V±10% 50Hz

Rated Power: 10 kW

Rated Current: 21 A

Fuse Protection: 32 A slow, on-site

Refrigerant: R-404A / R-23

Test Chamber Volume: approx. 190 litres

Weight: approx. 460 kg

For your security as a buyer, the following information:

The following steps are carried out in advance on our offered chambers:

1. Functional check and replacement of necessary components

2. If required, new filling with legally compliant refrigerant

3. Leak test with certificate

4. After a successful check, the chambers are subjected to a documented test run.

Itodpfx Ajv N Hc Ejfzer

Condition: used

Scope of delivery: (see picture)

(Technical data and information subject to change and error!)

We are happy to answer further questions by phone.

Mēs atvieglojam Jums meklēšanu: "damatomacchine forum"

Jūs uzreiz un bez maksas saņemsiet jaunos piedāvājumus pa e-pastu.

Jūs jebkurā laikā varat viegli izbeigt meklēšanas uzdevumu.

Lietots Damatomacchine Forum (688)

Tagad pilnībā pārskatiet Machineseeker ar vairāk nekā 200 000 lietotām iekārtām.Pārlūkojiet populārākos iekārtu nosaukumus:

Uzziniet tagad

+44 20 806 810 84

+44 20 806 810 84

Ievietot sludinājumu tagad

*par sludinājumu/mēnesī