Liesmas griešanas sistēmaPFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Liesmas griešanas sistēma

PFEIFER technology & innovation Plauen D

skyTUBE Pro 6500 3D RohrLaseranlage 6kW

Izgatavošanas gads

2026

Stāvoklis

Jauns

Atrašanās vieta

Plauen

Rādīt attēlus

Rādīt karti

Dati par iekārtu

- Mašīnas apraksts:

- Liesmas griešanas sistēma

- Izgatavošanas gads:

- 2026

- Stāvoklis:

- jauns

- Funkcionalitāte:

- pilnībā funkcionāls

Cena un atrašanās vieta

- Atrašanās vieta:

- Rathenaupl. 8, 08525 Plauen, Deutschland

Zvanīt

Tehniskā informācija

- Darba diapazons:

- 6 500 mm

- Ievades strāvas veids:

- trīsfāzu

- Kopējais platums:

- 1 629 mm

- Kopējais augstums:

- 2 525 mm

- Kopējais garums:

- 10 500 mm

- Galda garums:

- 6 500 mm

- Kopējais svars:

- 5 500 kg

- Jauda:

- 15 kW (20,39 zs)

- Lāzera jauda:

- 6 000 W

- Garantijas ilgums:

- 24 mēneši

- Aprīkojums:

- drošības gaismas barjera, dzesēšanas iekārta

Piedāvājuma informācija

- Ieraksta ID:

- A14903902

- Atsauces Nr.:

- skyTUBE6500 FIBER

- Pēdējoreiz atjaunots:

- 09.2.2461081

Apraksts

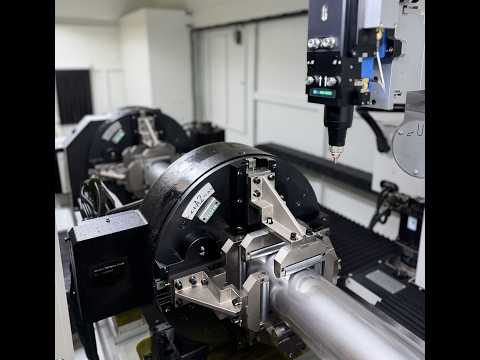

PFEIFER technology skyTUBE Pro 6500 X3 – Profile and Tube Laser Center 6500 x 15–160 mm Capacity

Nwodpfx Aerh Iw Teaqsc

The skytube-pro-6500×3 profile and tube fiber laser cutting system is designed for fast material changeover, offering up to 6kW of power for effective production—a smart and efficient tube laser processing solution. It covers laser cutting of round, square, and rectangular tubes, open and special profiles, maximizing productivity even with frequent production changes. The task: fiber laser power up to 6kW for a wide range of metalworking applications!

Unmatched Laser Cutting Performance

High axis speeds and accelerations paired with a robust mechanical structure enable excellent cutting performance and accuracy. This tube and profile laser machining center is made for production, requires minimum floor space, and is simply smart. Clever solutions—100% made in Saxony!

Tubes and profiles ranging from 15 x 15 up to 160 x 160 mm, 3D cutting with advanced fiber laser technology.

The semi-automatic 6-position profile and tube loading chain system allows for rapid job changeovers. With the optional bundle loader, you can operate independently.

Bevel Cutting

A game-changing function: Our machines can tilt the cutting head by up to 50° on a dedicated fifth axis. This solves one of the most significant issues in modern profile processing. If the laser beam always hits the tube perpendicularly, it results in an elliptical cut edge. The ability to tilt the laser head, in combination with the feed axis, allows for fully beveled cuts.

Safety First

Operating the skyTUBE Laser ensures peace of mind. The skyTUBE Pro is a Class 1 laser system—there is no risk of exposure to laser emissions or reflections during operation. For all our laser systems, safety and full compliance with the highest standards and regulations are our top priorities.

Technical Specifications:

- Sealed industrial housing, Class 1 laser as standard, Class 4 optional

- Working range of tube cutting system/chuck: round tubes 15 to 160 mm; rectangular tubes 15 x 15 – 110 mm

- Working area on the tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

- Automatic material feed: up to 6 x 160 mm profiles, lengths 3500–7000 mm

- Automated profile section unloading system, matched to profile length

- Z-axis drive: ball screw axis system with PTI SVZ system

- X/Y drive: linear axis system with PTI AC-SERVO system

- Productive cutting speeds: up to 50 m/min (material- and laser-dependent); acceleration up to 1.4G

- Software resolution: up to 2500 DPI

- Repeatability: ±0.03 mm

- Max. footprint dimensions (WxDxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system (depends on profile cut length)

Sludinājums tika tulkots automātiski, tāpēc tajā varētu būt dažas tulkošanas kļūdas.

Nwodpfx Aerh Iw Teaqsc

The skytube-pro-6500×3 profile and tube fiber laser cutting system is designed for fast material changeover, offering up to 6kW of power for effective production—a smart and efficient tube laser processing solution. It covers laser cutting of round, square, and rectangular tubes, open and special profiles, maximizing productivity even with frequent production changes. The task: fiber laser power up to 6kW for a wide range of metalworking applications!

Unmatched Laser Cutting Performance

High axis speeds and accelerations paired with a robust mechanical structure enable excellent cutting performance and accuracy. This tube and profile laser machining center is made for production, requires minimum floor space, and is simply smart. Clever solutions—100% made in Saxony!

Tubes and profiles ranging from 15 x 15 up to 160 x 160 mm, 3D cutting with advanced fiber laser technology.

The semi-automatic 6-position profile and tube loading chain system allows for rapid job changeovers. With the optional bundle loader, you can operate independently.

Bevel Cutting

A game-changing function: Our machines can tilt the cutting head by up to 50° on a dedicated fifth axis. This solves one of the most significant issues in modern profile processing. If the laser beam always hits the tube perpendicularly, it results in an elliptical cut edge. The ability to tilt the laser head, in combination with the feed axis, allows for fully beveled cuts.

Safety First

Operating the skyTUBE Laser ensures peace of mind. The skyTUBE Pro is a Class 1 laser system—there is no risk of exposure to laser emissions or reflections during operation. For all our laser systems, safety and full compliance with the highest standards and regulations are our top priorities.

Technical Specifications:

- Sealed industrial housing, Class 1 laser as standard, Class 4 optional

- Working range of tube cutting system/chuck: round tubes 15 to 160 mm; rectangular tubes 15 x 15 – 110 mm

- Working area on the tube: X 6500 mm, Y ±100 mm, Z 150 mm, A ±360°, U ±50°

- Automatic material feed: up to 6 x 160 mm profiles, lengths 3500–7000 mm

- Automated profile section unloading system, matched to profile length

- Z-axis drive: ball screw axis system with PTI SVZ system

- X/Y drive: linear axis system with PTI AC-SERVO system

- Productive cutting speeds: up to 50 m/min (material- and laser-dependent); acceleration up to 1.4G

- Software resolution: up to 2500 DPI

- Repeatability: ±0.03 mm

- Max. footprint dimensions (WxDxH): 11,600 mm x 2,830 mm x 2,100 mm + unloading system (depends on profile cut length)

Sludinājums tika tulkots automātiski, tāpēc tajā varētu būt dažas tulkošanas kļūdas.

Dokumenti

Piegādātājs

Piezīme: Reģistrējieties bez maksas vai piesakieties, lai iegūtu visu informāciju.

Reģistrēts kopš: 2011

Iesniegt pieprasījumu

Tālrunis & Fakss

+49 3741 ... sludinājumi

Šie sludinājumi varētu arī jūs ieinteresēt.

Mazā sludinājuma

Plauen

Plauen

1 083 km

Cauruļu un profilu lāzerslēdzējs

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

PFEIFER technology & innovation Plauen DskyTUBE Pro 6500 3D RohrLaseranlage 6kW

Mazā sludinājuma

Leipzig

Leipzig

1 005 km

Lāzera griešanas iekārta

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

12 m Rohrlaserschneidmaschine 12 kW12045ETP / 450 mm Option bis 510 mm

Mazā sludinājuma

Grebenau

Grebenau

1 203 km

Caurumošanas un locīšanas iekārta

BIHLERRM 35

BIHLERRM 35

Mazā sludinājuma

Deinze

Deinze

1 522 km

Cauruļu liekšanas mašīnas

ArloSPB60 CNC

ArloSPB60 CNC

Mazā sludinājuma

Loire

Loire

1 991 km

Fiber Laser Tube griešanas mašīna

Bodor T2

Bodor T2

Mazā sludinājuma

Saerbeck

Saerbeck

1 209 km

Lāzera griešanas iekārta

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

DURMAVorführ Rohrlaser HD-TC 60250 COMPACT

Mazā sludinājuma

Gondelsheim

Gondelsheim

1 372 km

Krāna jumtiņš Krāna portālkrāns

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Demag Hallenkran Brückenkran KranDKUN 10 ELKE 1600Kg 1,6t - Spur 11785mm

Mazā sludinājuma

Enschede

Enschede

1 251 km

Cauruļu lāzergriešanas mašīnas

Bodor K2

Bodor K2

Mazā sludinājuma

Debrecen

Debrecen

1 053 km

Lāzera griešanas iekārta

TRUMPFTruLaser Tube 7000 fiber

TRUMPFTruLaser Tube 7000 fiber

Mazā sludinājuma

Ludwigsstadt

Ludwigsstadt

1 124 km

Birstes noņemšanas mašīna

WeberTTS-1100

WeberTTS-1100

Jūsu sludinājums ir veiksmīgi dzēsts

Radās kļūda